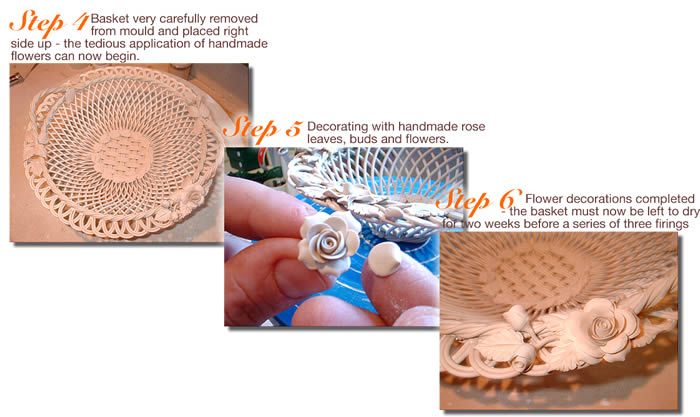

Production process at Hillgrove Porcelain.

Each piece is completely designed and made by me using the finest quality porcelain clay at my workshop at Hillgrove Carhan cahirciveen. I use different techniques to create the range of porcelain I make, from basket weaving, hand building and slip casting. Most of my work will have some degree of fine applied decoration eg flowers leaves birds all of which are made by hand.

When made the pieces are left to dry for 2 weeks before they receive their First biscuit firing which takes 10 hours up to 960 degrees. Next day they are removed from the kiln and thoroughly inspected for flaws which can be amended at this stage, now the pieces are ready to be dipped in the glaze and in this case is a very delicate operation as too thick the flowers would become drowned in the glaze too thin there would not be enough coverage to take the paint or the luster in the final stage.

Now they must dry for 7 hours approx and then each piece will have the Base wiped free of the glaze as if not done correctly the piece will stick to the kiln shelf. After loading the kiln they are now ready for the 2nd gloss firing up to 1280 degrees for 13 hours.

Next day all the pieces are removed from the kiln and again are inspected should they fail this inspection they are destroyed. Now all the beautiful white porcelain is ready for painting, lusters or decals which is all done by hand which can take many hours.

When finished the pieces are ready for their 3rd and final firing, this takes 7 hours to 820 degrees. When removed from the kiln each piece is finally inspected and will have their bases polished, and now finally after many weeks the pieces are ready to sell on line through my website or at my hillgrove Porcelain shop outlet 26 church st cahirciveen co kerry ireland.

All my work is signed Hillgrove Porcelain cahirciveen ireland.